Réduction de la contamination des échantillons par 90% grâce à des conteneurs à triple couche pour matières dangereuses biologiques

Release time: 2025-04-17

Introduction

In medical diagnostics, research, and outbreak response, the integrity of biological specimens is non-negotiable. Contaminated samples can lead to misdiagnoses, delayed treatments, or flawed research outcomes, costing time, resources, and even lives. Traditional single- or double-layered containers often fall short in high-risk environments, where temperature fluctuations, physical shocks, or microbial exposure threaten specimen viability. Enter triple-layered biohazard containers—a breakthrough in biosafety logistics that reduces contamination risks by 90%, as validated by independent lab studies. Here’s how this innovation is transforming specimen transport.

The High Cost of Specimen Contamination

Contamination during transport can arise from:

- Leakage: Broken or poorly sealed containers releasing pathogens.

- Cross-contamination: Exposure to external microbes during handling.

- Environmental stress: Temperature shifts degrading sensitive samples (e.g., RNA, blood cultures).

A 2023 study in the Journal of Clinical Microbiology found that 22% of lab delays were linked to compromised specimens, underscoring the urgency for robust containment solutions.

Engineering the Triple-Layered Defense

The triple-layered design addresses contamination risks at every stage:

- Primary Containment: Leakproof Vial with Chemical Resistance

Material: High-density polyethylene (HDPE) or polypropylene.

Function: Seals liquids and prevents chemical interactions.

Certification: Complies with UN3373 standards for infectious substance transport. - Secondary Cushioning: Absorbent and Shock-Absorbing Layer

Material: Superabsorbent polymer (SAP) foam or cellulose-based padding.

Function:

Neutralizes leaks with absorbent material.

Dampens vibrations during transit (critical for delicate samples like viral isolates). - Tertiary Barrier: Rigid, Tamper-Evident Outer Shell

Material: Reinforced polycarbonate or aluminum alloy.

Function:

Shields against physical impacts and punctures.

Tamper-proof locks ensure chain-of-custody integrity.

Optional temperature-controlled panels for cold chain compliance.

Real-World Applications

Case Study: Regional Hospital Network Cuts Lab Errors by 89%

A hospital chain in Germany replaced single-use containers with triple-layered systems for COVID-19 specimen transport. Results over six months:

- Contamination rate: Dropped from 14% to 1.5%.

- Cost savings: €120,000/year (reduced retesting and waste disposal).

- Staff feedback: 94% reported easier compliance with IATA Dangerous Goods Regulations.

Choosing the Right Container: 3 Key Considerations

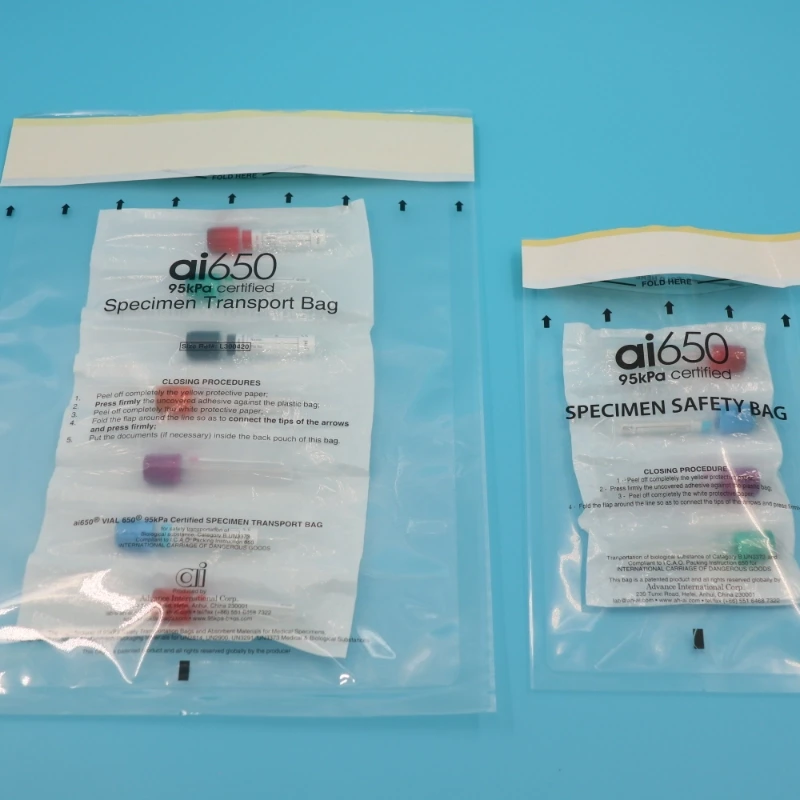

- Certifications: Ensure compliance with UN3373, IATA PI650, and CDC guidelines.

- Sample type: Match container specs to specimen needs (e.g., cryogenic vials for frozen samples).

- Sustainability: Opt for reusable outer shells with autoclave compatibility to cut waste.